When Is 3D Printing Most Cost-Effective?

Concerning prototyping, 3D printing is the most cost-effective process. Its evaluability in the prototyping scenario is brought in because it can eliminate unseen human errors and mistakes earlier during production instead of in the middle of costly mass production. It is the fastest and most reliable process of creating a prototype. As a designer, engineer, or hobbyist, you can easily and quickly 3D print a design, test it, and then make iterations of the prototype until it is ready for production using the fastest 3D printer.

When discussing cost-effectiveness, what are some costs that the 3D printer eliminates? Here they include;

- 3D printing facilitates parts consolidation, such as combining multiple parts into one, significantly reducing material and labor costs.

- In traditional printing, most objects would require custom tools for manufacturing, such as injection mold tools. But 3D printing facilitates direct digital manufacturing, eliminating purchasing specific expensive tools.

- 3D printing rapidly reduces inventory costs. How? Digital inventories enable a product to exist virtually. 3D printer users can print products on demand instead of stocking physical space with a costly surplus.

- Through lightweight strategies like hollow printing, 3D printing reduces the material used in part, reducing material cost.

Even though using 3D printing technology reduces project costs, it still needs to solve every manufacturing problem, especially concerning cost. Some costs drive the cost of printing, and they are essential to be considered; here are a few cost drivers to have in mind when 3D printing;

- While most 3D printers can run unattended, they still need an operator to maintain, set up, and unload the machine. Also, varying with the design, there may be some clean-up to achieve a perfect finished part using a high-accuracy 3D printer.

- It is evident that all 3D printing requires a digital file like a CAD file; typically, the user has to create this file, which radically alters the final cost for finished parts. Customizing a part for 3D printing may, at first, cost more upfront, but you will end up saving money in the long run.

- Apart from a direct cost for a part, some technologies need support structures. Therefore, these supports, whether breakaway or dissolvable, generally have to be accounted for after production.

- Some 3D-printed parts require downstream processing to achieve the ideal finished product. 3D printing is just one of the various steps in the production chain. For instance, in FDM 3D printing, the process flow starts from designing, loading the file to the printer, adjusting settings on the printer’s interface, and so on, until the final step.

3D printing provides unique value in typical product development and manufacturing applications through prototyping and manufacturing tools. In recent years, 3D printing has been used by various companies to send more cost-effective, innovative products to the marketplace at the ideal time. Often, the most direct cost for design in additive manufacturing can be managed and even rapidly reduced.

Testing the 3D printed products market and making adjustments is much easier when using 3D printing for manufacturing the product. Companies have become more agile with their capital due to 3D printing. They have realized they can allocate product budget tooling before seeing any sales first. Hence, manufacturers can follow parallel paths with ongoing product development and revision. So, 3D printing significantly changes companies’ supply chains by improving their return on investments in virtually all manufacturing sectors.

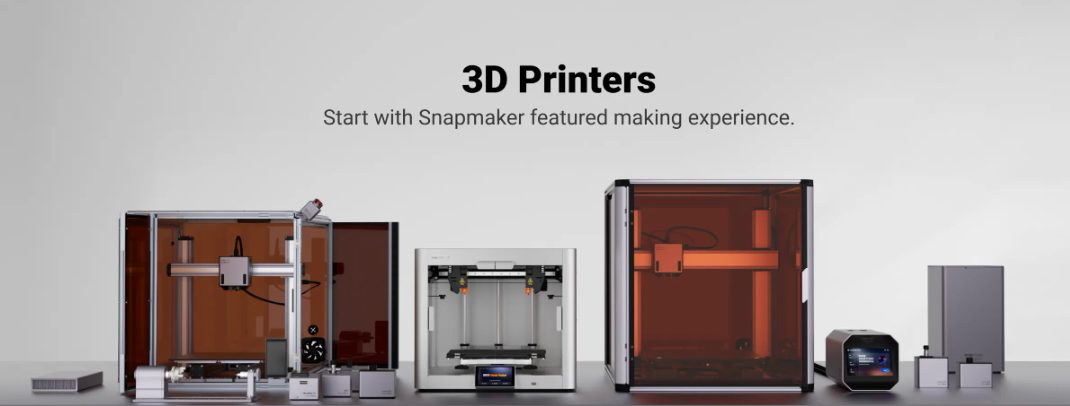

With all that said, we strongly recommend Snapmaker 3D printers for highly accurate 3D printing. Though offering a faster 3D printing process, their printers are known to ensure print quality isn’t compromised

3D printing provides unique value in typical product development and manufacturing applications through prototyping and manufacturing tools. In recent years, 3D printing has been used by various companies to send more cost-effective, innovative products to the marketplace at the ideal time Read more