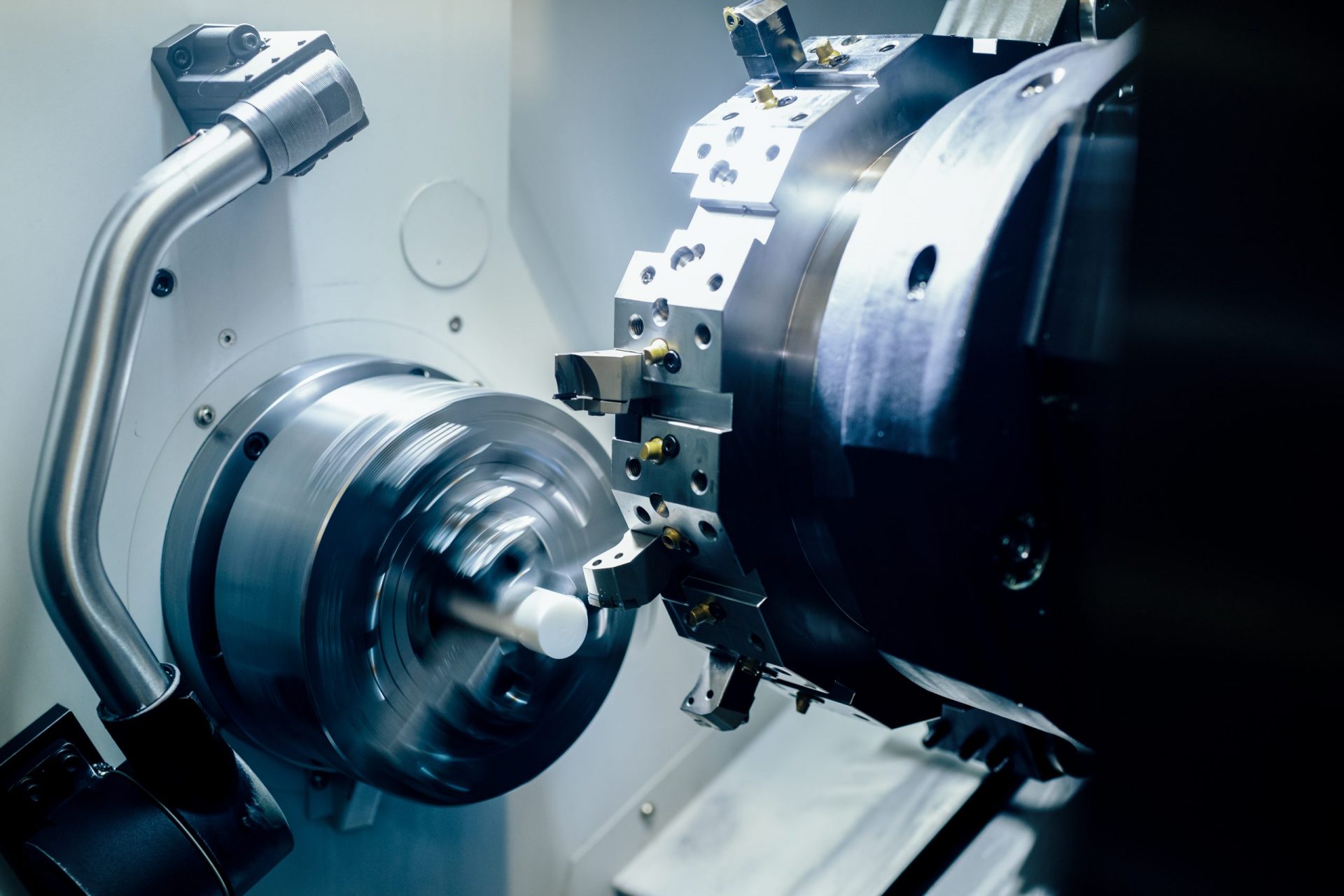

The Complete Guide of CNC Machining & It’s Services

WHAT IS CNC MACHINING?

CNC machining is one kind of reductive manufacturing technique in which material is removed from a product to achieve the desired shape. Computer numerical control (CNC) methods employ automated controls throughout the whole machining procedure, from start to end. CNC machining equipment may be programmed to repeatedly carry out the same guidelines, which can significantly increase the efficiency with which similar items can be mass-produced.

CNC equipment is available in various configurations and degrees of sophistication. The remaining material may be removed from any edge or angle using machines that can handle numerous tools simultaneously or operate across X, Y, and Z axes.

Components and parts are made with CNC machining in practically every field and purpose imaginable. The aircraft industry is only one example of a complicated sector that relies on large-scale machining projects.

When used with CNC machines, incremental optimization may find the most efficient method to turn a part. Simulations of these programs may be run to test the efficiency of the regulating program before it is implemented.

Instead of improving the design via experimentation and error, the final Cad/cam software will start showing results and providing worth from the very first iteration.

For production, this method is suitable for substrates like:

- Blended or Composite Materials

- Foam

- Glass

- Metals

- Plastic

- Wood

The automated features of CNC machining services are advantageous. Since automation makes machines run independently, fewer humans are needed to ensure high-quality component production.

Three stages of the production process: –

There are basically three types of manufacturing processes:

Reductive: – Machining is an example of a subtractive procedure, which means that it removes material from a product to generate a pattern.

Additive: – Combining or assembling individual parts into a whole is what additive manufacturing techniques do. For the most part, additive manufacturing takes the shape of 3D printing.

Formative: – The substrate is formed or otherwise altered throughout formative production to meet the specifications of the final product. In injection molding, for example, the substrate is melted and afterward compressed in a mold to retain a specific shape; this is an example of a formative manufacturing procedure. Metals may be bent or rolled as part of this process, among many others.

What are the benefits of CNC Machining?

Many factories employ machining methods because it allows them to produce several components from a given material. Following are the main perks of CNC are:

Productivity Boost:

Whenever needed, components may be made at factories equipped with computer numerical control machining. It’s possible that the machines can operate for extended periods with little oversight. Machines take up less room than work areas or mechanical machining sets, allowing more to be used in the same floor space.

A lot of precision:

CNC machining requires intricate procedures to be programmed. These protocols are strictly adhered to, with no room for human mistakes or deviation. All components shall be of the highest standard in terms of quality, accuracy, and consistency. Machine numerical control (CNC) manufacturing also allows the creation of items with complicated, elaborate patterns.

Getting things done more quickly:

CNC machining processes always begin with a CAD design. Therefore, prototype times are drastically reduced. The program discovers and avoids many design defects or problems associated with certain materials. The time it takes from product design to manufacturing may be cut by streamlining the prototype and testing phases.

Cost-effectiveness:

The manufacturing per unit cost is lowered because of the use of CAD files and the decreased likelihood of mistakes during production. CNC machining significantly saves production costs by reducing the amount of human labor involved.

Conclusion:

CNC Precision Machining is probably the best option to produce your unique components. It will save you money, time, and headaches while leaving minimal room for mistakes. Make use of this manufacturing technique immediately.